What to consider before buying an engine!

Quick overview of different marine powerplants.

Outboard engines: Motor and drives shaft are one unit, and usually mounted on the transom of a boat.

Inboard outboard engines: Are usually mounted inside a boat and the drive shaft is a leg usually mounted to the transom.

Inboard engines: The drive shaft is usually straight or vdrive configuration.

All these engines come now in diesel, gas, propane or natural gas.

Exhaust configurations: There is wet and dry exhaust. Each has benefits and problems.

Most commercial boats use dry exhaust, it is more reliable, but noisy and hot. For pleasure use, the wet exhaust is more common, the engine is quieter, but water aspiration and corrosion can be a problem.

Using diesel or gas engine?

Know what you are using the boat for, if one uses a boat for short duration gas is better. If one needs an engine that needs to run for long hours go diesel. Propane is available now for small out boards.

Is one engine enough?

Never rely on one engine! Always have a back up engine. The back up engine can be small. A good way to think about it is! If the main engine breaks down in a storm, can I control the boat. The back up can be paddles. Test it so you can paddle the boat and control it! Keep in mind the maintenance costs. Twin engine power boats maintenance double, whereas a small 10 hp kicker outboard costs are minimal.

Outboard engines

One can mount them on boats and remove them with ease, compact easy to maintain! All great until they are old! For example, repairing the outboards gearing requires specialized tools. Each model has its own specialty tools needed to repair gearing! It can make rebuilding an outboard challenging! Note the specialty tools are not always cheap and easy to obtain! One must take into consideration are the parts and specialty tools still available? When assessing an outboard that is showing age test the compression! Take a 10 hp outboard, if compression is less than 90 psi, trouble starting and problem with no spark. No point spending $300 to $500 on repairs. One can buy new outboard for $2000 to $3000. it means no headache reliable for years. Repair the old motor no guarantee when the next part will break. The worst part is! It will usually break, when out on the water!

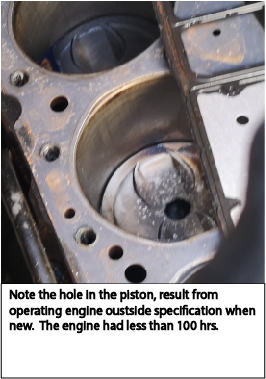

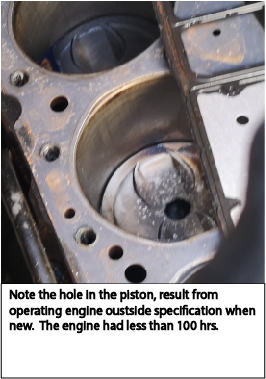

Rebuilt Engine is it any good?

Unlike cars and airplanes, a used engine is not beneficial unless it is an inboard engine! Reason corrosion protection on normal outboard engines is only warrantied for maximum 5 years. When one buys a rebuilt or 10-year-old out board engine, one can buy problems. It does not mean all old outboards are a problem, but if one does not know anything about outboard motors, do not buy used, buy new!

One can use rebuilt engines successfully, straight shaft, with cooling disconnected from sea water, preferably dry exhaust or stainless wet exhaust is best. Marine engines used within proper design parameters can last many years. 30 to 50 years is nothing unusual!

To keep engine safe!

Know the winterizing procedure for your engine and follow it! Make a clear date when the engine is winterized, and the boat is pulled out, so one does not forget!

Rely on more than one bilge pump, preferably have the pumps wired to two separate batteries. Have your wiring labeled that is going to battery. Imagine trying to identify your wiring in the dark in a rough sea!

On wet exhaust engines keep monitoring manifold temperatures, it should just be warm to the touch! Approximately 70 degrees Celsius. The cast iron manifolds need to be replaced at regular intervals of 5 to 8 years, in a sea water environment! It is beneficial to have flood sensor, automatic fire extinguisher and ventilation that works in the engine room. The problem with inboard engines is one does not see it when things go wrong!